Sika Raintite I

Sika Raintite I Specification

- Usage

- The concrete substrate must be sound and with a minimum pull off strength of 1.0 N/mm2. The substrate must be free of all traces of contaminants, loose and friable particles, cement laitance, oils and grease, wax, curing compounds, water repellent coatings etc. The substrate must be prepared by suitable mechanical preparation techniques such as high pressure water jetting, needle guns, grinding, blast cleaning etc. High spots must be removed by grinding. Weak concrete must be removed and surface defects such as blowholes and voids must be fully exposed. Repairs to the substrate, filling of blowholes/voids

- Purity

- ~0.5 N/mm2 (as bonding slurry)

- Application

- Waterproof coating Sika RainTite I : Cement =1 : 2 ~500 g/m2 per coat ~200 g/m2 per coat Waterproof brush topping Sika RainTite I : Cement : Fine Silica Sand=1 : 2 : 2 ~2 kg/m2 per mm thickness ~450 g/m2 per mm thickness Polymer modified cement mortar Sika RainTite I + adequate water : Cement : Fine Quartz Sand = 1 : 5 : 15 ~2100 kg/m3 ~50 g per mm thickness Bonding slurry Sika RainTite I : Cement = 1 : 2 ~600 g/m2 ~250 g/m2 for single coat Cement paint additive 10 % by weight of cement paint As per paint suppliers PDS ~2.5 kg per 25 kg cement paint

- Product Type

- BAG

- Main Material

- Acrylic copolymer and special additives

- Surface Treatment

- Polished

- Size

- 2 Kg

- Weight

- 20 Kilograms (kg)

Sika Raintite I Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- KOLKATA

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 20 Pieces Per Day

- Delivery Time

- 2 Days

- Sample Available

- No

- Sample Policy

- Within a certain price range free samples are available

- Packaging Details

- 20 kg pack

- Main Domestic Market

- East India, Bihar, Jharkhand, Odisha, West Bengal

- Certifications

- ~1.03 kg/L at +27 C

About Sika Raintite I

Hazardous components Chemical name CAS-No. Concentration (%) mixture of: 5-chloro-2-methyl-4-isothiazolin-3-one [EC no. 247-500-7] and 2-methyl-2H-isothiazol-3- one [EC no. 220-239-6] (3:1) (C(M 55965-84-9 >= 0.0025 - < 0.025 4. FIRST AID MEASURES General advice : No hazards which require special first aid measures. If inhaled : Move to fresh air. In case of skin contact : Take off contaminated clothing and shoes immediately. Wash off with soap and plenty of water. In case of eye contact : Flush eyes with water as a precaution. Remove contact lenses. Keep eye wide open while rinsing. If swallowed : Clean mouth with water and drink afterwards plenty of water. Do not give milk or alcoholic beverages. Never give anything by mouth to an unconscious person. Most important symptoms and effects, both acute and delayed : No known significant effects or hazards. See Section 11 for more detailed information on health effects and symptoms. Notes to physician : Treat symptomatically. 5. FIREFIGHTING MEASURES Suitable extinguishing media : Use extinguishing measures that are appropriate to local circumstances and the surrounding environment. Hazardous combustion products : No hazardous combustion products are known Specific extinguishing methods : Standard procedure for chemical fires. Special protective equipment for firefighters : In the event of fire, wear self-contained breathing apparatus.

More Products in Floor Hardener Category

Sika Topseal 109 Hi

Price 5420.0 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Consumption Layer Product Consumption Base coat SikaTop 109 Seal IN ~1 kg/m2 Top coat SikaTop 109 Seal IN ~1.2 kg/m2 Note: The consumption will vary depending on application area, substrate type, substrate roughness, surface profile, absorption of the surface and thickness required. Ambient air temperature +10 C min. / +40 C max. Mixing ratio Part A : Part B = 1 : 1.5 (by weight) Substrate temperature +10 C min. / +40 C max. Pot life ~40 minutes (100 g mass, +27 C)

Product Type : BAG

Surface Treatment : Polished

Usage : The concrete substrate must be sound and with a minimum pull off strength of 1.5 N/mm2. The substrate must be free of all traces of contaminants, loose and friable particles, cement laitance, oils and grease, wax, curing compounds, water repellent coatings etc. The substrate must be prepared by suitable mechanical preparation techniques such as high pressure water jetting, needle guns, grinding, blast cleaning etc. High spots must be removed by grinding. Weak concrete must be removed and surface defects such as blowholes and voids must be fully exposed. Repairs to the substrate, filling of blowholes/voids and surface levelling must be carried out using appropriate products from the Sikafloor , Sikadur and Sikagard range of materials. All dust, loose and friable material must be completely removed from all surfaces before application of the product, preferably by brush and/or vacuum. Any wax based curing compounds or water repellent coatings must be fully removed by scraping or grinding. All intersections of horizontal and vertical surfaces should be profiled with a mor tar fillet of minimum 25 mm 25 mm

Sikadur 53 UF Grout

Price 4880.0 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Precision seating of base plates Machine bases, seat base plates for light and heavy machinery including heavy impact and vibratory machinery, reciprocating engines, compressors, pumps, presses, etc. Bridge bearings Mechanical joints (i.e. road, bridge, deck etc.) Crane rails Ballast less rail tracks

Product Type : BAG

Surface Treatment : Polished

Usage : Sikadur 53 UF Grout may only be used by experienced professionals.

Sika Antisol A4

Price 14000.0 INR / Barrel

Minimum Order Quantity : 1 Barrel

Application : Sika Antisol A4 White is ready to use. Do not dilute. Stir well before use. Sika Antisol A4 White curing compound can be applied by a sprayer, brush or paint roller. For maximum beneficial effect, it should be applied immediately after disappearance of the surface water sheen following final finishing on horizontal surfaces. For vertical surfaces, apply immediately after removal of formwork. Apply single coat in two applications at right angles to each other to ensure uniform and more complete coverage. After application, the area must be protected from rain for at least 23 hours.

Product Type : BAG

Surface Treatment : Polished

Usage : Sika Antisol A4 White is sprayed on to newly laid concrete surfaces to form a thin film barrier against premature water loss, without disturbing the normal setting action. No need to remove Sika Antisol A4 White from concrete surface for subsequent application of acrylic water based paints, cement plasters, gypsum plaster, tile adhesives etc. We recommend to conduct compatibility test between Sika Antisol A4 White and subsequent application material before start of application of Sika Antisol A4 White.

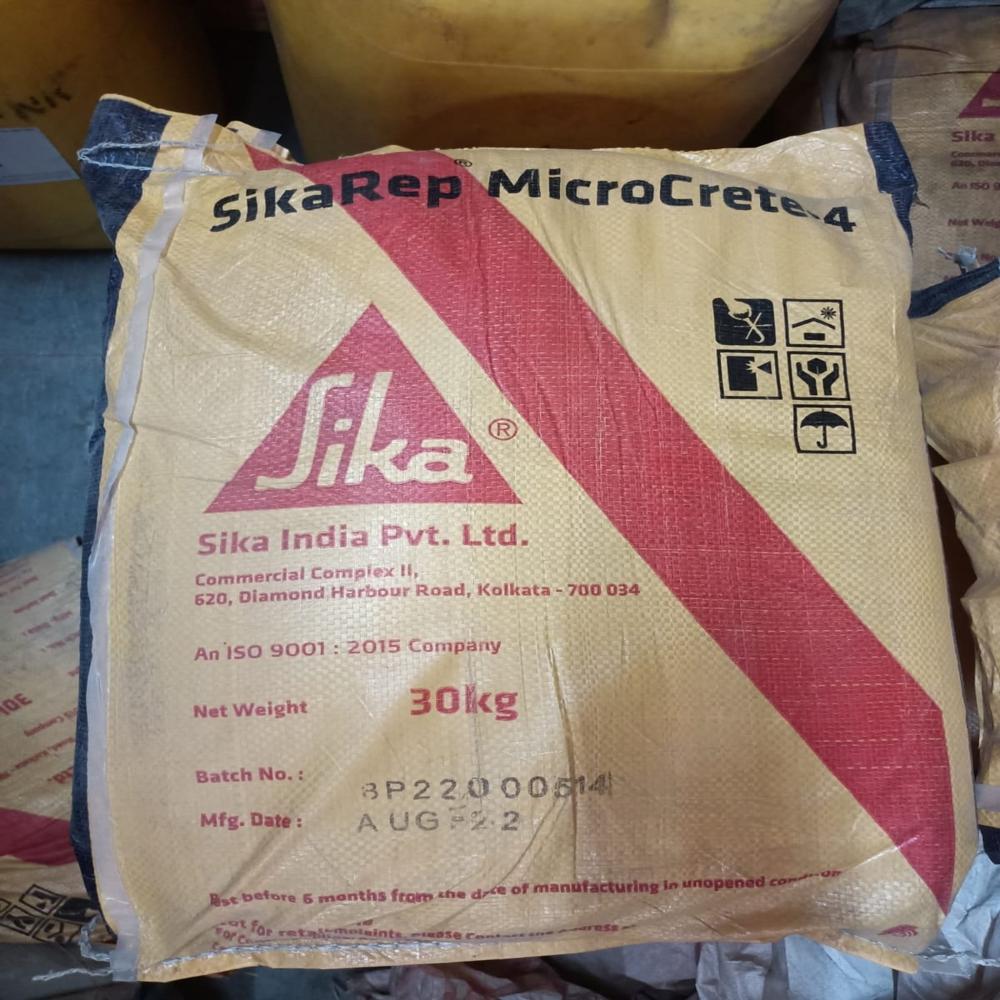

SikaRep Microconcrete 4

Price 327.0 INR / Bag

Minimum Order Quantity : 1 Bag

Application : SikaRep Microcrete4 is suitable for producing high performance microconcrete for deep repairs to all concrete structures such as: Highway bridges and culverts Whafts and jetties Tunnels and mines Dams and reservoirs Car parks and basements Power stations Sewerage and water treatment structures Anywhere where localised deep repair is required Anywhere additional thickness is required (column and beam jacketing, etc.) Structrural strengthening of structure by section enlargement

Product Type : BAG

Surface Treatment : Polished

Usage : No vibration needed Easily pumpable Easy to mix and apply Excellent flow characteristics Rapid strength development High ultimate strengths Impact resistant Noncorrosive Nontoxic Iron and chloride free Dense and nonshrink concrete created by dual stage expansion Good bonding with existing concrete Adjustable consistency by controlling the water within the recommended limit